1 Comment

even months after an incident occurred that can affect the “days away,” “transfer” and other information on the log. Tier 2 Reports – Has your company started any new processes this past year? Are there any new chemicals stored on site? If so, determine the quantities and how and where the materials are managed on site. Now is a good time to update your chemical inventory so that you are ready and able to prepare your Tier 2 Report. Tier 2 Reports are due March 1, 2021. And, don’t forget, a thorough and accurate chemical inventory supports other programs like Right-to-Know, oil and chemical spill prevention (SPCC and PIPP) and storm water pollution prevention. Air Permit Reports – Depending on your emission units and permit terms and conditions, you may have monthly, quarterly, semi-annual or annual reports to submit. It is a good idea to check in with the staff responsible for collecting data to ensure it is complete and accurate and that the data will be available when needed. Toxic Release Inventory – TRI reports aren’t due until July 1st. And although you still have some time, it is always a good idea to get a jump start on collecting necessary data, which can be time consuming and cumbersome. If you already know that chemical quantities exceed thresholds, start ordering 2020 data or reports from appropriate company departments and vendors now so you have plenty of time to assemble and analyze the data to prepare the TRI report and submit it on time. If you are unsure whether TRI Reporting is required, the first step is to conduct an Applicability Determination to identify whether regulatory thresholds have been exceeded. This activity examines the raw materials, processes and wastes generated by a facility and compares the results with the regulatory thresholds. If thresholds are exceeded, then a TRI report Form A or Form R are required. Online Reporting Access – Just like the fire department wants you to check the batteries in the smoke detectors at home during the New Year, it is also a great time to check your usernames and passwords to make sure they are current and still work so that your online access is not interrupted when you go to enter your data. Some agencies even require you to change your password annually. The new year is also a good time to make sure that everyone at the facility involved in the reporting process still knows their login information and how to use it. Getting these items resolved now will help avoid headaches as you approach reporting deadlines. If you have questions about reporting or applicability of regulations,

give us a call at (231) 288-1076. We are happy to help! If you have a process that contains highly hazardous chemicals, it’s likely that you are required to implement a Process Safety Management program at your facility. If you have established your program, then you already know that it is everyone’s responsibility to protect people and the environment from exposure to highly hazardous chemicals. And, having systems in place to prevent exposures and reduce the potential for catastrophic event like a significant release of toxic or flammable material is what Process Safety Management is all about. So, how does Process Safety Information (PSI) fit into this system?

The rule doesn’t provide allot of guidance on how to gather the information, what form it should take or what to do with the information once you have it. But we will get into these kinds of details later. As time goes on, we will explore each of the PSI requirements in future posts. Today we are going to focus on the purpose of PSI.

The Purpose of PSI The regulation simply states that, “The compilation of written process safety information is to enable the employer and the employees involved in operating the process to identify and understand the hazards posed by those processes involving highly hazardous chemicals.” In our opinion, though, PSI is the backbone of the PSM Program. PSI provides the building blocks for the rest of your PSM Program. And we are in agreement with Appendix C in that having complete and accurate PSI is essential for an effective PSM program. PSI is a core requirement. It is a necessity. Imagine, if accurate information is not maintained and something happens, how would you deal with the situation if you don’t know what kind of materials are in your process. It’s kind of like following a recipe, if you don’t know what the ingredients are, how do you know that your cake will turn out? If you don’t know what kind of gasoline your car runs on, how do you know what to put in it if you run out of gas? If you don’t know what kind of equipment is in your refrigeration system, how will know what to do when something needs repair or replacement? It’s the same principle. There is basic information you need to have on hand in order to run your process effectively and efficiently. So, let’s repeat the mantra. Complete and accurate PSI is imperative. It is really, Really, REALLY important because it supports everything else you do. How Does PSI Inform the rest of your PSM Program? PSI is the foundation of your entire PSM program. You use PSI to build your program. It intersects and interacts with all the other PSM program elements. We’ll keep it simple for now. Here are a few examples of how PSI affects the rest of your program:

Up Next – The details Over the next several months we will be posting some details about each of the required PSI. That is the information required by PSM and some guidance on what it should look like and how to use it. As businesses begin re-opening and more people are returning to work, it is good to know that OSHA has an understanding that some companies may have had difficulty complying with OSHA standards during the Pandemic shut-down.

OSHA published a Memorandum entitled, “Discretion in Enforcement when Considering an Employer's Good Faith Efforts During the Coronavirus Disease 2019 (COVID-19) Pandemic.” Even though this OSHA Memorandum was published in April, it is worth taking another look at it. The Memorandum explains that OSHA understands that COVID pandemic has created a lot of new and unusual situations to deal with at work, and that many factors have affected our businesses over the past several months that have hindered our ability to comply with OSHA standards, such as: 1) employees not showing up for work so they miss training sessions; 2) consultants not able to travel to your facility to perform an audit; 3) regularly scheduled testing was suspended to prevent the spread of COVID-19; and the list goes on. Not a Free Ride So, OSHA gets it and they are trying to take into consideration these hardships when it comes to your compliance or lack thereof. Now that COVID-19 cases are decreasing in some geographic areas, OSHA is returning to their original inspection planning policy for prioritizing and performing inspections. That should come as no surprise. The Inspectors are returning to their jobs too. But under the circumstances, and per the Memorandum, OSHA will be “Considering Good Faith Efforts” made to get work done and stay in compliance with OSHA regulatory requirements during pandemic. But, it is not a “Free Ride.” You don’t automatically pass Go and receive a pardon, so to speak. Instead, there are 3 stipulations to consider:

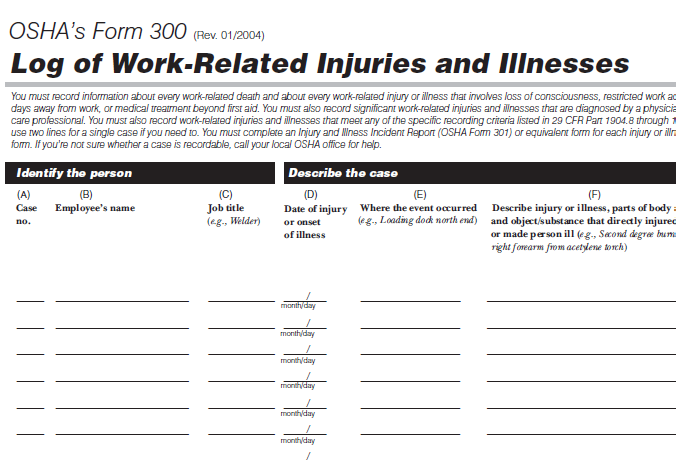

Let’s break this down. Annual or Recurring Requirements: In its memorandum, OSHA provides several examples in an Annex of types of situations where discretion can be applied. You can read the details for yourself here, but they include annual audiograms, annual HAZWOPER training, annual fit testing and Process Safety Management requirements. Good Faith Effort: Inspectors will be evaluating whether you have made a “Good Faith Effort” to comply with OSHA standards applicable to your site. What interim measures might have been employed if full measures could not be implemented to ensure employees are not exposed to hazards for which they were not trained? They will be asking you to demonstrate that you “thoroughly explored all options to comply with applicable standard”. For example, did you determine whether you could employ virtual or remote communication strategies to conduct training instead of holding in-classroom training. Demonstrate the “Good Faith Effort” to comply: This means you need documentation that demonstrates you made the effort. That could include letters (or emails) showing that a consultant has closed, a memo-to-file explaining your situation and how compliance could not be met because of pandemic-related circumstances. If you cannot demonstrate your effort to comply, the memorandum says that “a citation may be issued” according to current OSHA enforcement policy. And, if a citation is issued, OSHA may return to conduct a monitoring inspection. Summary OSHA will be using enforcement discretion on whether or not to issue a citation to those companies that can demonstrate that they were working in Good Faith to comply with OSHA’s periodic requirements, but the COVID-19 pandemic played a significant role in preventing their compliance. As always, it is best to be prepared with solid documentation, than it is to risk being cited when OSHA shows up at your door. Recording Reportable Injuries and Illnesses has always been challenging, and today we are once again faced with a new challenge called COVID-19. OSHA has posted some information on its web page to help employers with the recordable illness question. OSHA recordkeeping requirements at 29 CFR Part 1904 mandate covered employers record certain work-related injuries and illnesses on their OSHA 300 log.

This guidance is found at the following OSHA.gov link, in a blue box along the right side of the page. You can also visit OSHA’s Injury and Illness Recordkeeping and Reporting Requirements page for more information. 2155 W. Sherman Boulevard

Muskegon, Michigan 49441 (231) 288-1076

Stopping the spread of the virus is the only effective method we have of preventing more infections. Current prevention recommendations have included washing hands more often, cleaning contaminated surfaces and staying away from large gatherings. In response, trade shows and sporting events have been cancelled and churches and theatres are closing their doors for a week or two and are adopting a wait-and-see attitude. Universities and K-12 have extended spring break and cancelled on-campus classes and are moving to online learning until things improve. Recently, even bars and restaurants are being asked to restrict customers or only provide carryout. In the meantime, EHS professionals and HR departments should be following the recommendations from their local and state officials and from OSHA and MDHHS. Those recommendations are aimed at “flattening the Curve” (curve of infection) which means slowing the spread of infection to avoid overwhelming the healthcare system. See this article from the University of Michigan. So, the current infection curve for the COVID-19, that is the number of people becoming infected, is exhibiting an exponential increase. So, as time goes on, we see an increasing number of infected people at an increasing rate. The infection rate topic is illustrated in a Washington Post article that shows a simulated virus in some random, simulated settings. It’s all based on computer models, but it illustrates the point about spreading of infection. If we self-quarantine ourselves (within reason), even for a short while, we help slow down the spread of the disease. Agency Guidelines OSHA’s guideline 3990 can be found at this OSHA link. This guide provides lots of information about COVID-19 and recommendations for you to consider for inclusion in your Infectious Disease Preparedness and Response Plan (IDRP). Some topics you will find interesting include:

The MDHHS has Interim Guidelines for a variety of workplace, school, church and social settings. They include:

The bottom line for managing this disease is to be COVID-Wise, be prepared, avoid exposure and don’t spread it yourself. As always, arm yourself with knowledge. Keep up to date on the latest recommendations from your state and local officials. Here are some other good COVID-19 sources of information to share with your executives and workers: OSHA COVID-19 Web Page Center for Disease Control - COVID-19 Page MDHHS COVID-19 Web Page

The August 9, 2018 Federal Register provided OSHA’s latest amendments of the Beryllium rule (29 CFR 1910.1024) and delayed certain compliance deadlines. We think its helpful for the compliance deadlines to be outlined in chronological order. So we made a list for you. Below are the compliance dates (bolded) for the OSHA rule. If the MIOSHA dates are the same or different, it is noted. Listed below the compliance dates are the various paragraphs of 1910.1024 that are affected by the bolded compliance dates: March 12, 2018 – same for MIOSHA This is the compliance date for obligations contained in paragraphs (c), (d), (g), (k), and (l) of this standard.

December 12, 2018 – MIOSHA Part 340 is March 12, 2018. The amended rule sets this date as the compliance date for “all other obligations” of this standard such as:

March 11, 2019 – same for MIOSHA For paragraph (i) Hygiene Areas and Practices, the following requirements have been postponed until this new compliance date:

March 10, 2020 – same for MIOSHA For Engineering Controls required by paragraph (f) this is the new compliance date. However, It is believed that the intent here is for companies to comply with the non-engineering control portions of this section such as:

We’ll keep you updated on more OSHA and MIOSHA updates of this and other standards in future issues.  I can still remember it today. My first job as a safety manager for a manufacturer that had operations in four states, Canada and Mexico. Very exciting, and what a great opportunity for me to spread my wings …… that is until I started the job and discovered that my predecessor had been a safety Nazi and that the safety culture was old-school and just plain sour. I mean some people did not even want to be seen talking to me. I was seen as just another person who was going to tell them they could not make changes. On top of that, upper and middle management were not too keen on spending money implementing safety. Ya know it was just one of those “Soft” programs that take away from our bottom line, right? Argh!! I was questioning my career choice about that time. But I also saw an opportunity to grow and mature in the field and knew that I wasn’t the only person experiencing these problems. After all these years, I now see that my choice was a good one. However, I still run across companies with these same challenges. How do you get people (hourly and management) to “want” to talk about and implement Safety if they have never been educated as to the financial and production benefits? What do you do when they have been made to see Safety as something they have to do, instead of something that can improve the bottom line and make the factory floor a place where people enjoy working. In this newsletter series I will share with you some challenges I have encountered and some proven techniques I have used and have seen as effective over the 30 plus years I have been in the Safety business. Communication In those famous words spoken in the movie Cool Hand Luke “What we’ve got here is a failure to communicate,” one sees the challenge of an EHS professional. Ok, that’s a bit dramatic, but some days can be like that, right? Everybody is rushing around trying to get product out the door and doing everything in their power to get out of work on time to attend their kid’s soccer game or music recital or get to dinner or the bar. They don’t have time to listen to what YOU, the Safety person, have to say. Then, without warning, someone stops you and asks a question. And you think, this is your big chance to talk to someone about safety or environmental topics. To sell safety and even educate someone on EHS topics. Stop, breath, and think before you talk. Who is your audience? What is really important to this person? How much do they know about the topic in question? What priorities or hot button issues does their department have? What would you like to teach them about the topic or requirements? Selling Safety – One of the first things I tell new safety staff is that they need to always be ready to sell (and educate) people about safety. The worse thing we can do is be unprepared to answer questions. And we need to take our time in answering the questions as they come. After all, we are often in a hurry to get to a meeting, too. So we may not take the time necessary to really answer the person’s questions and make them a safety convert. Compound Interest – Think of safety converts this way. If you can convince one person a week that safety is worth their time and effort, in a year there will be 52 converts. Because people talk to each other, each of the converts will eventually convince a person or two or more, that safety is something worth their time, and before you know it half of the factory floor is part of your safety army. And, if your strategy includes influencing the influencers, then you can really get good results. The influencers are those people on the shop floor who are looked up to for one reason or another. They are leaders, outspoken, friendly to most people and may be quite popular. They can be line workers, line assistants, supervisors and others up the food chain. If they become converts, you’ve got it made. You’ve just multiplied your safety sales force. … a legal pyramid scheme! Avoid Regulatory Jargon - Try to keep the jargon and regulatory chatter at bay. Otherwise you might notice their eyes start to glaze over … you know, you’ve seen it… they’re still smiling but the words are not registering anymore. It doesn’t matter how many degrees or certifications you have, if someone doesn’t understand what you’re saying, the message will not get through. So, speak to people in their own language, free of our EHS jargon. Dosage – As EHS professionals we are concerned with risks associated with exposure, and exposure is measured in dosage. When talking to non-EHS professionals, always consider the size and complexity (doses) of information you provide at any one time. Use language that they understand, not regulatory jargon or text book talk. For example, dole out information in sound bites that people can digest and easily repeat to others in their department. If you are having problems with people using too many extension cords say something like this: About 1/4 of all industrial structure fires are caused by electrical distribution and lighting equipment. While this NFPA statistic does not call out extension cords specifically, a connection can be made and a seed of concern can be sewn (or planted) in a simple sound bite. Engage People – For years OSHA has said that involving workers in EHS activities and decision-making causes them to care more about and implement changes. We see that in our Lean Manufacturing and 5S scenarios too. EHS changes created through employee involvement last longer than if we just tell people to do it. The reason for this is that they now have ownership of the change. So, when an employee complains and asks why they have to do something a certain way, start with asking them to show you the issue at hand. This gets people engaged on the topic and will help you understand the scenario and where the issue is located. Ask them their opinion and about possible solutions to the problem, whether the answer is obvious or not. People have lots of opinions and are happy to share them with you. This engagement helps you build a relationship and provides an opportunity to discuss with them the physical and regulatory aspects of the issue and people can start to see and appreciate more sides to the issue. Empathy – Safety professionals have to practice looking at every disagreement situation from the other person’s point of view. If you can see their point of view and why they feel the way they do, then you will have an insight into how to effectively communicate with them, and what information may be useful during the communication. There is usually a little tenuous history associated with workplace situations, some that have existed for years. Sometimes you can work around these tenuous issues and sometimes you can’t, but talking about them almost always helps. Effective listening is one way to show empathy. Effective Listening – Speaking of effective listening, everybody wants to be heard. Employees in a big factory tend to get lost in the hustle and bustle of getting those orders out. Depending on the quality of their supervisor they may withdraw and lay low just to get through the shift. Effective listening means spending the time, eye contact, asking follow-up questions, paraphrasing what you heard and parroting. All these communication techniques help tell the person that you are listening and you care about their opinion. Patience – Many people don’t like change. As a result, sometimes you need to give people some extra time to let the change sink in and get comfortable with the idea. It’s a time for you to put your communication skills to work. If it’s a change in PPE requirements, sometimes it takes a little more effort like stopping in a day or two after the change to see how the PPE is working. I participated in a situation where we upgraded PPE for a cleaning line and added face shields and nitrile aprons to protect worker’s skin, eyes and clothing from caustic cleaner. There was one particular worker who hated the change and he was outspoken and not easy to talk to on a good day. So, being the caring safety professional that I was, instead of hiding in my cozy office, I made a point of heading out there in the middle of the next shift to see how he was doing. Well, I got an earful as soon as I arrived at the workstation. Too hot, can’t see, the cleaner was still getting on the person’s face. So, I left and went back to my cozy office ….. to get a note pad to do another Job Safety Analysis. But this time the JSA was not so much on the work station and the PPE, but rather on how the person was performing the job with the equipment and PPE assigned. I was patient and let the worker explain his side, I showed empathy and we objectively looked at it from all sides - together. What we found was that the person was being reckless with the cleaning equipment, causing lots of overspray, and he kept touching his face with his glove that had caustic cleaner residue on it. Long story short, we talked, I listened, he listened. With the supervisor’s participation we made some changes to the work station that the worker suggested, and he made some adjustments on how he did his job, and he promised to try harder to keep his hands away from his face. And, after a few more days, he was not so grumpy and not having any problems. In fact, he later became an assistant line leader and he was tasked with helping other workers at that same workstation avoid some of the problems he encountered. He became part of the solution. He was selling safety! And, you know what else? He stopped being the grumpy complainer and started coming up with other improvements to the line that actually made it run better! But, remember, what led to that was an opportunity for him to be heard and become part of the solution and take ownership of the solution. Hey, maybe employee participation works after all! Next time … How Important is Your Attitude Toward Other People? Author: Bill Schneider, CHMM |

|

RSS Feed

RSS Feed