|

Here are a few recent recalls and their links that may be of interest. You can look up more recalls at the U.S. Consumer Product Safety Commission website. Whirlpool Recalls Microwaves Due to Fire Hazard.

Cree Recalls LED T8 Lamps Due to Burn Hazard; Includes T8 Lamps Provided as Replacements in Previous Recall. Polaris Recalls Ranger Recreational Off-Highway Vehicles Due to Fire and Burn Hazards. Polaris Recalls RZR XP Turbo Recreational Off-Highway Vehicles Due to Fire Hazard; Severe Burn Injuries; Includes Previously Recalled RZR Turbo ROVs.

0 Comments

In May 2016, OSHA issued a new Letter of Interpretation for the Process Safety Management (PSM) standard's Recognized and Generally Accepted Good Engineering Practices (RAGAGEP) requirements originally outlined in the PSM Standard (29 CFR 1910.119). OSHA notes that this “memorandum rescinds and replaces the memorandum of the same title dated June 5, 2015.” It is intended to clarify OSHA’s policy but does not include any substantive changes to their enforcement policy related to RAGAGEPs. OSHA does a good job of adding details into the policy that we as practitioners have known for quite some time. The details provided help in making requirements clearer. There is a lot of good information in the revised policy. I just want to touch on a few things here. The first important change to note is this document is now referred to as an “Enforcement Policy” rather than a letter of interpretation or memorandum. There can no longer be any doubt or misinterpretation that the information provided is a requirement rather than just a guideline.

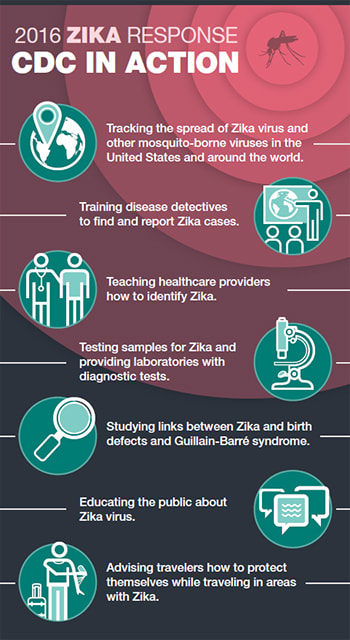

Secondly, it is well known that the PSM regulation is considered a “performance oriented standard.” That means that the regulation does not necessarily outline exactly what you have to do. The Standard defines what has to be accomplished, but it doesn’t tell you exactly how you get there. Instead, it is up to the Employer to decide which codes, standards and practices it will put in place, implement and monitor. Both the 2015 and 2016 versions of the policy provide examples of RAGAGEPs, but the 2016 version clearly states that the items provided in the policy are “examples” and that “employers select the RAGAGEPs they apply in their covered processes” and then demonstrate that they are meeting them. It also notes that there may be more than one code or standard necessary to meet all of the hazards presented by a particular process. Both versions state that an employer should not “cherry pick” the provisions of codes and standards because codes and standards are meant to be implemented as a whole. Selectively choosing a portion of a code or standard could result in inadequate control of a process hazard. But, the 2016 version also acknowledges that internal standards incorporating select provisions may be adequate, but OSHA would review these on an individual basis. Lastly, documentation is key. I think we all already knew this. But oftentimes, when reviewing inspection and testing procedures, there is no mention of where the inspection and test schedule came from. The 2016 policy clearly states that OSHA compliance officers will review the employer’s written inspection and testing procedures to determine the selected RAGAGEP. Identifying all the source documents (e.g., codes, standards, etc.) in the company’s written procedures is a must. It cannot be “understood” that refrigeration systems comply with IIAR standards, it must be stated as such in a procedure, and the standards must be referenced. To read the entire memorandum on the OSHA website, click here. We have all seen the news reports on and off since last year about the Zika outbreak in Brazil and its spread throughout the Caribbean and US Territories. Well, it is officially here in the lower 48 states and there are some things everybody needs to know and take seriously in order to avoid being infected by or spreading the disease. OSHA, USEPA and the Center for Disease Control (CDC) have web sites with lots of information and guidelines to help people protect themselves and their loved ones from the virus. Are there actually ZIKA cases here in the US? Yes. The CDC has a web site that identifies the reported cases by state. Bottom line is that there are few states without reported cases. But, remember, these are “reported” cases and does by no means indicate the actual number of cases out there. States with no reported cases may actually have people who are infected that have gone unreported. Is this a scare tactic? Yes. We are dealing with a new disease and with new data that is still being compiled and studied. We should take the warnings and precautions offered by the agencies seriously to avoid uncomfortable future conversations regarding Zika Virus infections and pregnancy. Can the Virus Spread from Person to Person? Yes. However, this is where some scientists disagree on all the facts and are still investigating cases and modes of transmission. An uninfected mosquito that bites an infected person can become infected itself, and then spread that virus to an uninfected person. The CDC has a web site that shows the [known] range for the mosquitos [most likely] to spread the disease. However, as we have seen with other disease vectors that factors like climactic changes and our ever-traveling human race can promote the spread of certain diseases to other uninfected areas. And besides, mosquitos don’t carry signs that say what kind they are, and last time I looked I could not differentiate between a Culex quinquefasciatus, Aedes albopictus or a Aedes aegypti. ….. I can’t even say these words!....... The Zika virus can also be spread from mother to child and through intimate personal contact between people. These are topics that I am going to let the health professionals talk to you about. In the meantime you can read the CDC guidance on people to people transmission and I recommend you contact your doctor with questions regarding your specific situation.

Bottom line is that we should be conservative until the scientists are done researching this whole mode-of-transmission issue. Assume the virus is in your state and that all mosquitos can spread the virus and take appropriate precautions. How Do I Protect Myself, My Family and Our Employees? Bite Prevention - The good news is that Bite Prevention is made up of methods that are mostly familiar and easy to implement. These include mosquito repellents, wearing clothing over more of our bodies instead of less, and wearing that attractive netting over our heads (ok, it’s not attractive). Guidelines also include tips for how to best use repellents with clothing. The OSHA guidelines on worker protection can be found here. The CDC guidelines can be found here. Eliminate Standing Water - Eliminating places for mosquitos to breed is also important and is included in the guidelines. Make sure there are no areas of stagnant water where mosquitos can breed such as open trash cans, old tires, clogged gutters. And try to avoid wet mosquito rich areas in the first place. Bug Repellent - There is nothing like that pungent smell of bug repellent to remind us that summer is finally here. USEPA has a searchable web site that lists over 600 registered mosquito and tick repellents and includes their active ingredients and length of time effectiveness. The list includes repellents that contain DEET, Picaridin, IR3535, Citronella Oil and Oil of Lemon Eucalyptus to name a few. USEPA qualifies the information by saying that the data are based on technical information provided by each of the companies that manufacture or sell the products. The list can also be downloaded in PDF format and is found here. Click on the following topic to obtain more information: Transmission and Risk Surveillance and Control of Aedes aegypti and Aedes albopictus in the United States OSHA NIOSH Interim Guidance on protecting workers from Zika CDC Zika, etc. web site USEPA Mosquito-Tick Repellent Web page and info This month’s Q&A corner focuses on questions regarding Hazard Communication and the new Respirable Crystalline Silica standard. Hazard Communication

Q: How often do we need to do Haz Com training? A: Haz com training is required:

NOTE: Some companies provide refresher training annually as a best practice. Q: Does HazCom training only cover chemical hazards? A: No. HazCom training covers any physical and health hazard in a work area. Due to labeling requirements, we tend to get conditioned to think that HazCom only applies to the chemicals in our work areas. Q: Is combustible dust a hazard that we need to train on? A: Combustible dust is identified as a physical hazard, and if present in your facility you will need to train on combustible dust hazards. Q: Do you need to keep SDSs for commercial products such as "Windex" and "White-Out"? A: OSHA does not require that SDSs be provided to purchasers of household consumer products when the products are “used in the workplace in the same manner that a consumer would use them.” [i.e.; where the duration and frequency of use (and therefore exposure) is not greater than what the typical consumer would experience]. This exemption in OSHA's regulation is based, however, “not upon the chemical manufacturer's intended use of his product, but upon how it actually is used in the workplace.” Employees who are required to work with hazardous chemicals in a manner that results in a duration and frequency of exposure greater than what a normal consumer would experience would need to be trained in those hazards. For example, if a manufacturer uses Windex to clean stainless steel panels all day long, this could be considered as a duration and frequency condition (exposure) much greater than the average home owner (consumer). As a result, companies would need to have the SDS for Windex, and train their employees on its hazards. Q: What about janitorial use of chemicals? A: Janitorial use of chemicals is not considered to be the same duration and frequency of exposure scenario as a consumer (home owner). Janitors use the chemicals during extended periods and likely have a higher exposure. Chemical SDSs used for janitorial purposes should be maintained at the facility by the employer in charge of the janitorial services. Information on interpretations of OSHA’s hazard communication standard can be found here. Silica Q: What kinds of operations present a crystalline silica hazard? A: According to OSHA, industries and operations in which exposure to crystalline silica can occur include, but are not limited to:

Q: What is the Silica Compliance Schedule? A: The final rule took effect on June 23, 2016. Industries have 1 to 5 years to comply with most requirements, based on the following schedules:

Information on OSHA’s Silica rule can be found here.

|

|

RSS Feed

RSS Feed