Some companies have chosen to make their COVID-19 Preparedness Plan a separate document, while others have just incorporated these new activities into their existing Haz Com plan. Either way is fine as long as you can demonstrate that you are following the applicable OSHA guidance and Executive Orders.

What we are doing, in essence, is looking at COVID-19 as a new hazard introduced into the workplace that can cause death or serious injury. We should treat Covid-19 just like we would any other occupational hazard, and use OSHA’s COVID-19 guidance to help measure the risk posed by certain workstations, sick employees and visitors. Then we determine the steps the employer needs to take to eliminate or reduce this new hazard. These are considered reasonable steps in assessing and abating a hazard. Let’s do a Deeper Dive into What this would look like: As we know, OSHA requires that employers provide a safe working environment, one that is free from recognized hazards that can cause death or serious physical harm. Enforcement is done using the General Duty Clause and other applicable and specific regulations. We typically create a safe workplace by conducting hazard assessments and then developing engineering solutions and procedures on how to abate the hazards and protect employees and people who visit the facility. If we simply treat COVID-19 as a new serious hazard in the workplace, then the OSHA requirements that we need to consider come into focus. These include hazard assessment, safe work practices and hierarchy of controls (engineering and PPE). We can then prepare a COVID-19 Preparedness and Response Plan with the recommendations in OSHA’s COVID-19 Preparedness Guide (OSHA 3990). Here are the recommended steps:

We also need to consider Executive Orders that provide insight on required best practices. These best practices fall into five categories:

If it Wasn’t Written Down, Then it Didn’t Happen This last step is very important. Document everything you do. Remember, the old OSHA adage still applies. “If it is not written down, then it didn’t happen.” In addition to your plan, document and maintain training records, entry screening results and the steps taken to isolate a confirmed or suspected case of COVID-19, and appropriate notifications to the health department and others. Having appropriate documentation that describes the actions planned and actions taken because of an exposure will be especially important when employees complain to OSHA or an agency conducts an inquiry at your facility. You will need to be able to demonstrate how you provided a place of employment free from recognized hazards, including COVID-19. And you will do that using your written hazard assessment, policies and procedures, engineering controls and required PPE. Litigation related to COVID-19 injuries, fatalities and human resource issues is an emerging legal market, so it is extremely important that you have a plan and document everything the company has done to provide a safe work environment. Together they will demonstrate the company’s good-faith efforts taken to deal with the new hazard and be useful in resolving compliance or legal disputes when they arise. Lastly, as restrictions are loosened and we begin to reopen, remember not to get sucked into the free-for-all of not worrying about COVID-19 prevention. Many states are currently re-imposing restrictions after seeing spikes in COVID cases as a result of people not being careful enough. We don’t want to invite this behavior into our businesses. We don’t want to contribute to the infection rate, so it will be important to re-emphasize with employees that they need to stay vigilant at home and at play to prevent the spread of infection to family, friends and co-workers. Here are some links to useful information and guidance that will help you navigate COVID-19 as you re-open. If you have a process that contains highly hazardous chemicals, it’s likely that you are required to implement a Process Safety Management program at your facility. If you have established your program, then you already know that it is everyone’s responsibility to protect people and the environment from exposure to highly hazardous chemicals. And, having systems in place to prevent exposures and reduce the potential for catastrophic event like a significant release of toxic or flammable material is what Process Safety Management is all about. So, how does Process Safety Information (PSI) fit into this system?

The rule doesn’t provide allot of guidance on how to gather the information, what form it should take or what to do with the information once you have it. But we will get into these kinds of details later. As time goes on, we will explore each of the PSI requirements in future posts. Today we are going to focus on the purpose of PSI.

The Purpose of PSI The regulation simply states that, “The compilation of written process safety information is to enable the employer and the employees involved in operating the process to identify and understand the hazards posed by those processes involving highly hazardous chemicals.” In our opinion, though, PSI is the backbone of the PSM Program. PSI provides the building blocks for the rest of your PSM Program. And we are in agreement with Appendix C in that having complete and accurate PSI is essential for an effective PSM program. PSI is a core requirement. It is a necessity. Imagine, if accurate information is not maintained and something happens, how would you deal with the situation if you don’t know what kind of materials are in your process. It’s kind of like following a recipe, if you don’t know what the ingredients are, how do you know that your cake will turn out? If you don’t know what kind of gasoline your car runs on, how do you know what to put in it if you run out of gas? If you don’t know what kind of equipment is in your refrigeration system, how will know what to do when something needs repair or replacement? It’s the same principle. There is basic information you need to have on hand in order to run your process effectively and efficiently. So, let’s repeat the mantra. Complete and accurate PSI is imperative. It is really, Really, REALLY important because it supports everything else you do. How Does PSI Inform the rest of your PSM Program? PSI is the foundation of your entire PSM program. You use PSI to build your program. It intersects and interacts with all the other PSM program elements. We’ll keep it simple for now. Here are a few examples of how PSI affects the rest of your program:

Up Next – The details Over the next several months we will be posting some details about each of the required PSI. That is the information required by PSM and some guidance on what it should look like and how to use it. As businesses begin re-opening and more people are returning to work, it is good to know that OSHA has an understanding that some companies may have had difficulty complying with OSHA standards during the Pandemic shut-down.

OSHA published a Memorandum entitled, “Discretion in Enforcement when Considering an Employer's Good Faith Efforts During the Coronavirus Disease 2019 (COVID-19) Pandemic.” Even though this OSHA Memorandum was published in April, it is worth taking another look at it. The Memorandum explains that OSHA understands that COVID pandemic has created a lot of new and unusual situations to deal with at work, and that many factors have affected our businesses over the past several months that have hindered our ability to comply with OSHA standards, such as: 1) employees not showing up for work so they miss training sessions; 2) consultants not able to travel to your facility to perform an audit; 3) regularly scheduled testing was suspended to prevent the spread of COVID-19; and the list goes on. Not a Free Ride So, OSHA gets it and they are trying to take into consideration these hardships when it comes to your compliance or lack thereof. Now that COVID-19 cases are decreasing in some geographic areas, OSHA is returning to their original inspection planning policy for prioritizing and performing inspections. That should come as no surprise. The Inspectors are returning to their jobs too. But under the circumstances, and per the Memorandum, OSHA will be “Considering Good Faith Efforts” made to get work done and stay in compliance with OSHA regulatory requirements during pandemic. But, it is not a “Free Ride.” You don’t automatically pass Go and receive a pardon, so to speak. Instead, there are 3 stipulations to consider:

Let’s break this down. Annual or Recurring Requirements: In its memorandum, OSHA provides several examples in an Annex of types of situations where discretion can be applied. You can read the details for yourself here, but they include annual audiograms, annual HAZWOPER training, annual fit testing and Process Safety Management requirements. Good Faith Effort: Inspectors will be evaluating whether you have made a “Good Faith Effort” to comply with OSHA standards applicable to your site. What interim measures might have been employed if full measures could not be implemented to ensure employees are not exposed to hazards for which they were not trained? They will be asking you to demonstrate that you “thoroughly explored all options to comply with applicable standard”. For example, did you determine whether you could employ virtual or remote communication strategies to conduct training instead of holding in-classroom training. Demonstrate the “Good Faith Effort” to comply: This means you need documentation that demonstrates you made the effort. That could include letters (or emails) showing that a consultant has closed, a memo-to-file explaining your situation and how compliance could not be met because of pandemic-related circumstances. If you cannot demonstrate your effort to comply, the memorandum says that “a citation may be issued” according to current OSHA enforcement policy. And, if a citation is issued, OSHA may return to conduct a monitoring inspection. Summary OSHA will be using enforcement discretion on whether or not to issue a citation to those companies that can demonstrate that they were working in Good Faith to comply with OSHA’s periodic requirements, but the COVID-19 pandemic played a significant role in preventing their compliance. As always, it is best to be prepared with solid documentation, than it is to risk being cited when OSHA shows up at your door. It is that time of year. The “Dog Days of Summer.” In many areas of the Midwest it is expected to be hot and humid. Workers young and old are being exposed to heat and humidity but may not yet be acclimated. Let’s review some important principles of heat exposure and the signs and symptoms of heat exhaustion and heat stroke. Signs, Symptoms & First Aid The first thing to know is how to recognize the signs and symptoms of heat cramps, heat exhaustion and heat stroke.

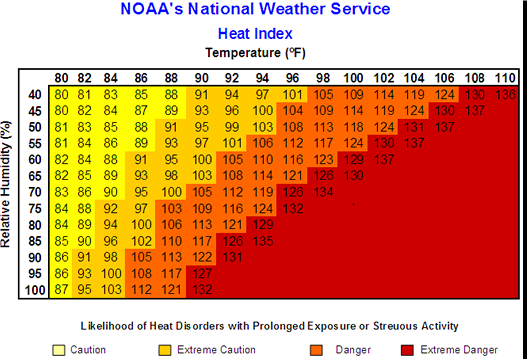

Heat Stress Regulations & Guidance There are no specific regulations for heat stress, but MIOSHA, OSHA, ACGIH, NIOSH and NOAA all have guidance and information to educate employers on how to keep workers safe from heat induced illnesses. A good place to start is the Heat Index published by NOAA. Heat Index: The heat index is the “feels like” temperature we hear from the local weather station and it incorporates both temperature and humidity. The higher the heat index the hotter it will feel and the greater the risk of workers experiencing heat-related illness. The index is broken into four levels of risk: Caution; Extreme Caution; Danger and Extreme Danger. Humidity Matters

Relative humidity is the amount of moisture in the air. The higher the humidity the harder it is for the body to cool itself through evaporation of sweat resulting in the air temperature feeling hotter. Contrary to that, very low humidity can also cause problems if our sweat evaporates too quickly causing dehydration if a person does not drink enough water. An important side-note about the NOAA heat index is that the values were developed for shady, light wind conditions. This is a critical consideration because exposure to full sun can increase heat index values by up to 15 degrees F. As a result, solar load needs to be considered when developing protective measures for a particular job or work site. ACGIH Threshold Limit Value In the back of the ACGIH TLV and BEI booklet is a Thermal Stress section that includes heat stress and strain guidelines. The section includes a decision tree, the use of Wet-Bulb Globe Temperature, clothing adjustments and other criteria to provide a TLV and action level for planning purposes to avoid heat strain. The section also includes warnings about the TLV being based on the ability of most healthy people who are also acclimatized. The TLV does not apply to people with prior heat stroke, heat exhaustion, cardiac or kidney problems, pregnancy, obesity or older workers, among others. Heat-Related Illness Prevention Plan Whether you are looking at ACGIH, OSHA or other heat stress guidance, having a plan for a particular job or job site that will be proactive in protecting workers is a plus. Depending on the environmental conditions, acclimation of workers and their overall health, some plan elements are as follows:

The following links have some helpful information for developing and implementing a Heat-Related Illness Prevention Plan, including an OSHA-NIOSH Heat Safety app downloadable to a cell phone: |

|

RSS Feed

RSS Feed