Some of the biggest changes in the rules include:

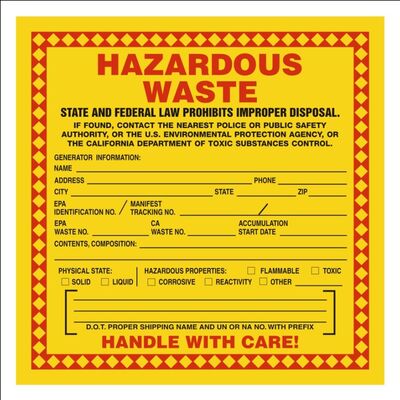

Generator Category Name Change – Knowing where your operation falls in the regulations is important to navigate the regulation. The adoption of GIR replaced the old category Conditionally Exempt Small Quantity Generator with Very Small Quantity Generator (VSQG). Remember, each type of generator has a different set of waste management requirements. Suffice it to say that VSQGs have fewer requirements than do LQGs. Labelling - VSQGs must label their containers that contain hazardous wastes to identify the contents, while SQGs and LQGs must label hazardous wastes containers with the words “Hazardous Waste”, the waste codes, accumulation start date and another label or marking identifying the hazard associated with the waste. SQG Re-Notification: SQGs are now required to re-notify EGLE every 4 years regarding their generator status. The re-notification must be completed by September 1st of the 4th year. SQGs who have not previously notified EGLE must complete the Site Identification form (EQP-5150) and submit it to EGLE by September 1, 2021 or earlier if an ID number is needed for manifesting hazardous waste. Waste Determination: Each hazardous waste must be characterized, meaning a generator must determine if any of its waste streams are considered hazardous waste. The information gathered during the characterization process must be documented and kept for 3 years. Information used to characterize waste can include knowledge of the process generating the waste, analytical results from sampling the waste, and SDSs from raw materials that went into generating the waste, among other things. Aerosol Cans – For generators in Michigan, this is a big change. Now, aerosol cans can be classified as Universal Waste rather than hazardous wastes, as long as aerosol cans are managed in accordance with the Universal Waste Rules. The rules include requirements for labelling and managing of containers, defines aerosol can processing, and includes recordkeeping and training requirements. Some general universal waste requirements that apply to aerosol cans include:

There are some other advantages to classifying aerosol cans as universal wastes rather than hazardous wastes. Aerosol can puncture systems are cost-effective options. The company will likely save money by separating the can from the liquid rather than merely sending partially full aerosol cans off as hazardous waste. A puncture system removes liquids from the aerosol cans and accumulates it in drums and the aerosol propellent is absorbed into the can puncture system filter, and the empty aerosol cans are then placed in the scrap metal bin. In addition, EGLE has established air permitting exemptions for on-site puncturing of miscellaneous and surface coating hand-held aerosol cans. Episodic Waste Generation Events – Making the regulation more flexible for generators and to resolve a historic problem facing many VSQGs and Small Quantity Generators (SQGs), the GIR allows a company to temporarily exceed its monthly generator quantity without bumping the company into a more stringent generator category. Some of our clients are excited about this change because oftentimes after a plant clean-out or a production change, they are left with more hazardous waste than they would normally generate. Sometimes a spill creates an unplanned quantity of cleanup debris that must be managed as hazardous waste. This unplanned event often bumps a company into a more stringent generator category. Previously, if a generator were to exceed a monthly generation rate threshold for its generator class, the company had to comply with all of the rules for the more stringent generator classification. Now, using the Episodic Waste Generation Event, a generator can exceed its generator classification threshold once per year without being thrust into the more stringent regulatory category. Of course, there are a few conditions that must be met in order to qualify for the Episodic Waste Generation event:

Waste Consolidation – Another new rule that provides more flexibility is waste consolidation. A company that owns and operates a VSQG facility and a Large Quantity Generator (LQG) facility can consolidate the VSQG facility’s wastes at the LQG facility if both facilities are under the control of the same person (as defined in the rule) and they meet certain conditions: Some VSQG conditions include:

LQGs must meet the following conditions:

These are just some of the highlights of the new GIR. Here is a Link to the EGLE HW GIR page where you can read more. If you have questions regarding the new requirements and how they can benefit your operation, please contact one of us at SRM and we will help you navigate your way through the new rules. (231) 288-1076.

Believe it or not, Michigan is in the process of adopting the federal Hazardous waste Generator Improvement Rule (GIR) sometime this Spring. Now I know what you’re thinking, Trump was supposed to get rid of all those pesky hazardous waste rules. Well, he is still working on that, but in the meantime the Michigan legislature is doing something that makes sense for the hazardous waste management community. The GIR became effective (as far as the feds go) back in May 30, 2017. EGLE is off the hook for adopting the rule until the Michigan legislature adopts the rule which is currently in the works. No, we still don’t have an effective date for Michigan’s version of the rules, but it is hoped that EGLE will know in the next few months. This final rule includes over 60 changes to the GIR regulations that clarify existing requirements, increase flexibility, and improve environmental protection. Some changes reorganize the regulations or make minor technical corrections. Here are some of the highlights: Episodic Waste Events: Allowing a very small quantity generator (VSQG, formerly CESQG) or a small quantity generator (SQG) to maintain its existing generator category in the case of an event in which the VSQG or SQG generates a quantity of hazardous waste in a calendar month that would otherwise bump them into a more stringent generator regulatory category. We have worked with clients as they wrestled with the old rule after they performed a cleanup, plant maintenance, found obsolescent chemicals on their premises, or they made changes to operations that left them with a large amount of chemicals they no longer needed and it threw them over the limits. Allowing episodic waste events will be a welcome change. Waste Co-Mingling: This rule provides some cost savings to companies by allowing a VSQG to send its hazardous waste to a sister company (with the same owner/operator) so that it can be consolidated with the larger facility’s waste streams and then be sent to a TSDF. Emergency Response Plan Notifications: The rule includes Local Emergency Planning Committees among those organizations with which a generator may make response arrangements. Quick Reference Guides: The GIR requires that new and existing LQGs submit quick reference guides to local emergency responders. The quick reference guides are intended to provide easy access to key information during an event. SQG Re-Notification: SQGs will be required re-notify EGLE every four years regarding their generator status. Currently, SQGs only notify once under the current system. Labeling and Marking Containers: GIR revises the regulations for the labeling and marking of containers and tanks so that these labels and markings clearly indicate the hazards of the waste contained inside the container. Keep up on the latest regarding GIR by checking out the EGLE GIR web page. We’ll also keep an eye on it and report back in future newsletters. The USEPA published a final rule, entitled, “Management Standards for Hazardous Waste Pharmaceuticals and Amendment to the P075 Listing for Nicotine” in the Federal Register on February 22, 2019. According to the USEPA announcement, the final rule establishes cost-saving, streamlined standards for handling hazardous waste pharmaceuticals to better fit the operations of the healthcare sector while maintaining protection of human health and the environment.

This final rule will help protect drinking and surface water reducing the amount of hazardous waste pharmaceuticals entering waterways by 1,644 to 2,300 tons on an annual basis. To accomplish this the rule will prohibit disposal of pharmaceuticals in the sanitary sewer by all facilities subject to the rule. This action will help address the issue highlighted by a growing body of publicly available studies documenting the presence of pharmaceuticals in drinking and surface waters as well as their negative impacts to aquatic and riparian ecosystems. In addition, FDA-approved, over-the-counter nicotine replacement therapies (i.e., nicotine patches, gums and lozenges) will no longer be considered hazardous waste when discarded. This will result in significant cost savings and burden reduction in the management of these types of nicotine wastes. Finally, the final rule reaffirms EPA’s long-standing policy that non-prescription pharmaceuticals and other unsold retail items that have a reasonable expectation of being legitimately used/reused or reclaimed are not solid waste. It also provides regulatory certainty that the Resource Conservation and Recovery Act (RCRA) applies when healthcare facilities send unused, unsaleable prescription hazardous waste pharmaceuticals to reverse distributors to receive manufacturer credit. Simultaneously, the rule incorporates flexibilities to accommodate current reverse distribution business practices to facilitate its implementation. SRM will keep you posted on this important development.  Beginning July 1, 2018, all hazardous waste shipments from small and large quantity hazardous waste generators, and all shipments of polychlorinated biphenyl (PCB) waste, requiring a uniform manifest, must be submitted to the U.S. EPA for tracking in the online e-Manifest system. The receiving TSDF is responsible for submitting the e-Manifest information it receives to the U.S. EPA. It is also responsible for paying any e-Manifest processing fees due to the U.S. EPA following deployment. To ensure a smooth transition, generators are encouraged to review e-Manifest resources shared with them by their TSDF and to review resources on the MDEQ and USEPA websites. Highlights for Generators

The eManifest online system is located in the USEPA CDX online system under RCRA Info and is currently available to explore. You will need to open a CDX account if you don’t already have one. There is a Youtube video from USEPA that walks you through a fictitious site and may be helpful. To get more information, check out the MDEQ and USEPA resource pages, or contact SRM for assistance. The next Hazardous Waste Biennial Report deadline is March 1, 2018 and covers activities during calendar year 2017. The Michigan DEQ will not be sending biennial packets to waste generators. Instead, Large Quantity Generators and TSDFs will be required to report using the federal forms and instructions.

While the MDEQ will accept paper copies, it is encouraging facilities to submit their Biennial Report data electronically through the Biennial Report component of the USEPA RCRAInfo Industry Application (RIA). The RCRAInfo login page can be used to set up a RCRAInfo account and login. The web site provides guidance and information to be followed to prepare and submit the report. Additional information for submitting Biennial Reports to the MDEQ either electronically or on paper can be found at the MDEQ web site for Biennial Reporting. By now you should be knee deep in assembling information reviewing data and getting ready to prepare and submit your Q1 reports.

OSHA 300A Logs – Your OSHA Log Posting is due February 1st. Make sure you have re-reviewed some 2016 incidents with your incident investigation team to ensure you have all the information you need and that it is still current. Sometimes reporting information changes weeks and even months after an incident so you want to be sure days away, transfer and other information is still correct. Hazardous Waste Biennial Report – Review your waste shipping records to verify you have all the original signed manifests, LDR documents and waste characterization files for all wastes generated during 2016. Do a quick generator status check to determine whether or not your generator status has changed. Tier 2 Reports – Has your company started any new processes this past year or started storing new chemicals on site? If so, determine the quantities you now store and how the materials are managed. This is a good time to update your chemical inventory. Air Permit Reports – Depending on your emission units and permit terms and conditions, you may have monthly, quarterly, semi-annual and annual reports to submit. It is a good idea to check in with the staff responsible for collecting the data to ensure it will be available when needed and it is accurate. Online Reporting Access – Just like the fire department wants you to check the batteries in the smoke detectors in your home, the new year is a good time to check your online access user names and passwords to make sure they are current and still work. Some agencies require you to change your password annually. The new year is a good time to make sure that everyone involved in the reporting process still knows their login information. Getting these items resolved now will help avoid headaches as you approach reporting deadlines. If you have questions, give us a call and we will be happy to help. |

|

RSS Feed

RSS Feed